|

Working principle

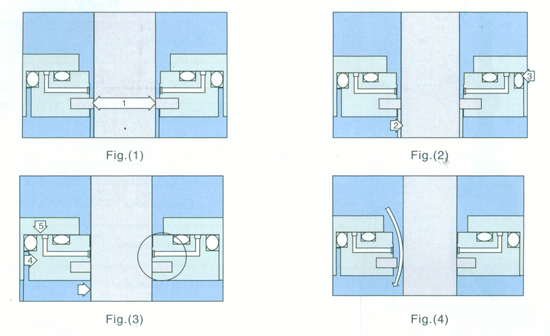

1.With equal pressure throughout the valve (and the gate in closed pposition),and initial seal(1) is formed with the raised PTFE ring on the faces of the seats,(The seat-inserts clean both sides of the gate each time the valve is opened or closed)

2.As line pressure(2)is appulied to the vavlve,it acts on the gate,forcing it against the PTFE ring on the downstream seat,compressing it until the seat against the steel seat.Thus,a double seal is formed...first,a PTFE-to-metal seal;then,metal-to-metal.The seat is also forces firmly into its recess .The O-ring(3)prwvents any downstream flow at this point.

3.Upstream seal is provided when valve cavity pressure is bled off.This is caused by the force of line pressure acting against the uostream seat(4)moving the seat against the gate and providing a tight PTFE-to metal seal at this point.At the same time,the O-ring(5)forms a tight seal with the seat recess.

4.Valve automatically relieves itself of excessive valve cavity pressure.When valve cavity pressure exceeds line pressure...from such causes as thermal expansion...the upstream seat is forced back into into its recess and the excess pressure in the valve cavity is bled between the seat and the gate into the line.

Flow charalteristic

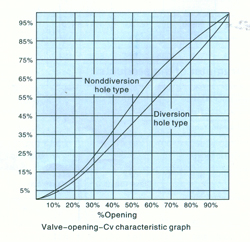

The flow characteristic of flat gate valves with a diversion hole is equal to that of pipelines of thesame specification.The characteristic is shown in per centum form.As for valves without a diversion hole,its cavity fly span is smaller than that of wedge gate vales and it is a regular cylindrical object,therefore,characteristics of the valves are similar except that they have a larger pressure loss.Besides,their flux adjustment behavior is better than that of the ones with a deversion hole.

上一页 [1] [2] [3] [4] [5] [6] [7] 下一页 |