|

| 一、Brief introduction of product |

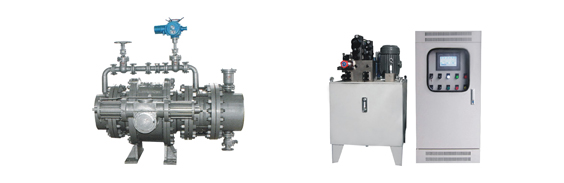

Power plant hydraulic control slow closing ball valve is a valuable complementarity for the hydraulic control slow closing butterfly valve. It specially fits for high head

water power plant. It coordinates with hydroturbine, working as per the hydraulic transition principle, effectively eliminates the water hammer effect and ensures reliable shut-

off of pipeline by preset program, therefore, protects the safety of pipelines. This series of hydraulic control slow closing ball valve is with high degree of intelligence, complete

functions, reliable performance and low flow resistance coefficient, the flow resistance coefficient at full opening is similar with the pipeline.We also provide tailor-made

solutions according to user’s unique requirement and meet the users needs in every aspects.

1 . Low flow resistance. ball valve is with the lowest flow resistance among the valves, even if the reduced port ball valve, the flow resistance is still very low.

2. Swift and convenient opening and closing. By turning 900 , the ball valve completes full opening or full closing action, which makes it ideal for fast opening and closing.

3. Excellent sealing. The seat ring of ball valve is mainly resilient material like PTFE, which ensures perfect sealing, furhtermore, the sealing strength of ball valve increases simultaneously with the medium pressure.

5. The ball valve achieves opening and closing by rotating 900 , which makes it easy to realize automatic control and remote control. Ball valve can be equipped with pneumatic actuator, electric actuator, hydraulic actuator, gas over oil actuator or electric hydraulic actuator. |

| 二、Design and manufacturer standard |

Design and manufacturing: GB/T14478 GB/T12237

Flange Standard:GB/T9112-9124 GB12380.1-12380.3

Standard of Energy storage vessel: GB/T2352 |

Actuation: JB/T5299

Face to face length:GB/T12221

Inspection and test: GB/T14478 GB/T13927 |

| 三、Basic Parameters |

| Oil Pump electricity supply |

AC380V/50Hz |

Control power supply |

DC220V |

| Design pressure of pump station |

31.5MPa |

Working pressure of pump station |

13-16MPa |

System Pressure Setting

|

Upper Limit

|

16MPa |

Working pressure of oil cylinder

|

13-16MPa |

| Lower limit |

13MPa

|

Hydraulic olfor pump staion |

N46-N68号 |

Nominal diameter DN (mm)

|

300-1600

|

Nominal diameter |

<700

|

≥700 |

NOminal Pressure PN( Mpa)

|

2.5-10 |

Opening time(90 Degrees)

|

10-60S10-60S(Adjustable) |

30-90S |

Ps(Mpa) Testing Pressure

|

Seat |

1.1×PN |

Closing time (90 Degrees)

|

Fast closing

|

3-20S |

6-30S |

| Shell |

1.5×PN |

Slow closing |

6-60S |

10-90S |

Workina Pressure(MDa)

|

≤1.0×PN |

Shut off the valve angle |

Fast closing

|

70±10 Degrees |

70±10 Degrees |

Medium temperature(℃)

|

≤80 |

|

Slow closing |

20±10 Degrees |

20±10 Degrees |

| Applicable Medium |

Water, Sea water, Slurry, Oil etc |

Protection Level |

lp56 | |

| 四、Mian prts and materia |

| Part Name |

Material |

| body |

Ductile lron,Carbon steel |

| Ball |

Ductile iron,Carbon steel |

| Shaft |

Stainless Steel,Carbon Steel |

| Seat |

PTFE; PPL |

| Ball seat |

Stainless Steel |

| Bushing |

CSB Self-Iubricated bearing |

| Packing |

V-shape sealing ring,Flexible graphite |

| Transmission box |

WCB |

|

|

| |

|