|

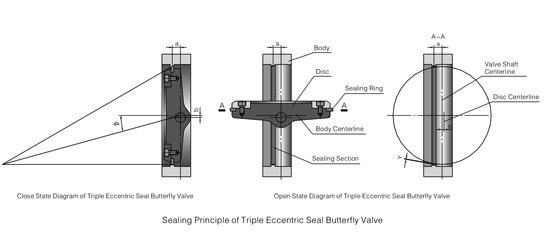

4. Sealing Principle of Triple Eccentric Seal Butterfly Valve

A βeccentric is formed up between the centerline of seat and the centerline of body on the base of double eccentric butterfly valve, making disc sealing face immediately disengaged from seat sealing face upon the opening of butterfly valve, and in close contact with the seat sealing face upon closing. When fully opened, a gap Y which is the same as that in double eccentric seal butterfly valve, is formed up between the two sealing faces. The design of this type of valves has thoroughly eliminated the mechanical wear and scratch between the two sealing faces, making the sealing performance and service lift of butterfly valves greatly improved. When valve is closed, with sealing ring under the extrusion of body sealing face and disc, two upward elastic deformations are produced. The sealing face is fallen under outward tension at long shaft and inward compressive stress at short shaft. The long and short shafts produce elastic deformation of different directions, thus to maximizing the sealing force between the sealing faces of valve.

This distinctive eccentric combination not only uses cam effect, but also eliminates friction completely, thus to ensure no friction between seat and sealing ring on disc during the 90°stroke of valve, a perfect solution to clear away the possibilities of abrasion and leakage.

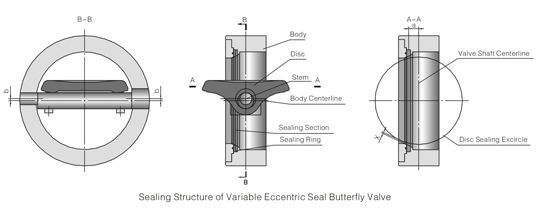

5. Sealing Principle of Variable Eccentric Seal Butterfly Valve

The distinctive feature of variable eccentric butterfly valve is that, the stem shaft where disc is mounted is a three-segment eccentric shaft. The two ends of the three-segment stem shaft are concentric, while the centerline of the middle segment is deviated from the axial lines of the two ends by a center-to-center distance. Disc is just mounted on the middle segment. This eccentric structure forms up a double eccentric shape when disc is completely opened, and a single eccentric shape when disc is turned to be closed. Under the force of eccentric shaft, when tending to be closed, disc will move somewhat toward the sealing conical surface of the seat, and then engaged to perform dependable sealing. When seat sealing face is abraded after a period of service, adjust the driving mechanism to make the close position of disc forward for some degrees, in this way to set up a new sealing state.

上一页 [1] [2] [3] [4] 下一页 |