| Product features |

|

1 . ALL the components are faged ones.

2. Lower-Ioading Stem and backward sealing construcbon have been setup for posicive Sea|ing at stcffling position and backing-out protecting of the handle.

3. Interbedded valve seat is applied on whose back RO-nng is also mounted for avoiding the leakage of mediu |

| Main Parts and Materriais |

Main Performance Specification |

| Accessory name |

Material |

| GB/ASTM |

| Body、bonnet |

A105、F304、F316、F316L、F51、LF2 |

| Sealing Ring |

RPTFE、PPL、PEEK |

| Ball |

A105+ENP、F304、F316、F316L、F51 |

| Seat |

A105+ENP、F304、F316 |

| Oring |

Rubber、Viton |

| Stem |

410、A105+ENP、F304、F316

F316L、F51、 |

| Stud\Nut |

35F、B7/2JH、B8/8 | |

PN(Mpa)

Nominal

diameter |

Test pressure(Mpa) |

shell

|

High-pressure

Liquid sealing |

Low-pressure

Hermetic sealing |

16.0

|

24

|

17.6

|

0.6 |

| 32.0 |

48 |

35.2 |

| Applicable temperature |

-40-80℃ |

Applicable medium

|

Water.oil products,nitrogen,ammonia,

Hydrogen, and liquefied gas,etc. | |

|

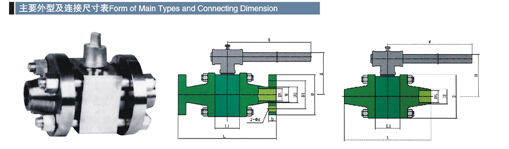

PN(Mpa)

Nominal

diameter |

PN(mm)

Nominal

pressure |

(mm)Main dimension |

| L |

L1 |

D |

D1 |

H |

|

M |

D2 |

b |

Z-Φd |

| flange |

Butl-weld |

flange |

Butl-weld |

flange |

Butl-weld |

flange |

Butl-weld |

flange |

Butl-weld |

Flange |

| |

10 |

210 |

150 |

52 |

60 |

95 |

90 |

60 |

18 |

77 |

58 |

220 |

M24x2 |

18 |

20 |

3-Φ18 |

| |

15 |

230 |

170 |

62 |

70 |

95 |

100 |

60 |

23 |

85 |

62 |

220 |

M24x2 |

20 |

20 |

3-Φ18 |

| |

20 |

240 |

190 |

73 |

80 |

105 |

110 |

68 |

29 |

94 |

75 |

250 |

M33x2 |

28 |

20 |

3-Φ18 |

| |

25 |

260 |

205 |

77 |

95 |

105 |

115 |

68 |

36 |

100 |

80 |

250 |

M33x2 |

28 |

22 |

3-Φ18 |

| |

32 |

300 |

230 |

100 |

110 |

115 |

150 |

80 |

43 |

120 |

96 |

300 |

M42x2 |

38 |

24 |

4-Φ18 |

| 16.0 |

40 |

350 |

260 |

110 |

120 |

165 |

170 |

115 |

49 |

150 |

111 |

400 |

M52x2 |

48 |

30 |

6-Φ26 |

| |

50 |

400 |

330 |

130 |

140 |

165 |

200 |

115 |

61 |

165 |

128 |

450 |

M64x2 |

58 |

32 |

6-Φ26 |

| |

65 |

490 |

360 |

140 |

150 |

200 |

225 |

145 |

80 |

180 |

180 |

500 |

M80x3 |

74 |

40 |

6-Φ29 |

| |

80 |

580 |

380 |

150 |

160 |

225 |

270 |

170 |

105 |

200 |

200 |

600 |

M125x2 |

94 |

50 |

6-Φ33 |

| |

100 |

620 |

430 |

178 |

188 |

260 |

320 |

190 |

118 |

245 |

245 |

800 |

M125x4 |

115 |

60 |

6-Φ36 |

| |

10 |

210 |

150 |

52 |

60 |

95 |

90 |

60 |

18 |

77 |

58 |

220 |

M24x2 |

18 |

20 |

3-Φ18 |

| |

15 |

230 |

170 |

62 |

70 |

105 |

100 |

68 |

23 |

85 |

62 |

220 |

M33x2 |

28 |

20 |

3-Φ18 |

| |

20 |

240 |

190 |

73 |

80 |

105 |

110 |

68 |

29 |

94 |

75 |

250 |

M33x2 |

28 |

20 |

3-Φ18 |

| |

25 |

260 |

205 |

77 |

95 |

115 |

115 |

80 |

36 |

100 |

80 |

250 |

M42x2 |

35 |

25 |

4-Φ18 |

| |

32 |

300 |

230 |

100 |

110 |

135 |

150 |

95 |

43 |

120 |

96 |

300 |

M52x2 |

41 |

30 |

4-Φ22 |

| |

40 |

350 |

260 |

110 |

120 |

165 |

170 |

115 |

49 |

150 |

111 |

400 |

M64x2 |

47 |

35 |

6-Φ26 |

| |

50 |

400 |

330 |

130 |

140 |

200 |

200 |

145 |

61 |

165 |

128 |

450 |

M80x3 |

70 |

40 |

6-Φ29 |

| |

65 |

490 |

360 |

140 |

150 |

225 |

225 |

170 |

80 |

180 |

180 |

500 |

M100x3 |

90 |

50 |

6-Φ33 |

| |

80 |

580 |

380 |

150 |

160 |

260 |

270 |

195 |

105 |

200 |

200 |

600 |

M125x4 |

112 |

55 |

6-Φ36 |

| |

100 |

620 |

430 |

178 |

188 |

300 |

320 |

235 |

118 |

245 |

245 |

800 |

M155x4 |

135 |

65 |

8-Φ36 | |