| Summary: |

Metal to Metal Seat Ball Valve is an important scientific researching product. It is mainly applied to the delivery othigh temperature, slurry dust substances etc.

GJ Metal to Metal Seat Ball Valve owns not only various advantages of common industrial ball valves, but also particularand outstanding characteristice in heat-durability, especially when soft seal could not be used, such as in pipeline delivery of medium with high friction dust,slurry, and solid foreign matters mixture.

The seat is of stainless steel body with Stellite alloy pile-up welding. The ball is of stainless steel body,with th reesu rface treatment technique as hard chrome plating, vacuum coating and tungsten-titanium alloy and Stellite alloy pile-upwelding etc. Adopted so as to meet the heat resisting and wear resisting requirement. GJ ball manufacturing process iscreative, which realizes high-accuracy and super mirror suriace processing of the ball. Another featu re of the metal seat ballvalve is spring prepressing seat, which ensure the absolute reliability of seal and stability of operating torque. It ensuresabsolute safety, sealing reliability and operating flexibility and convenience in structural design. |

| Characteristic: |

1、 Long life ball·seat

The seat is of Stellite alloy surface, and the ball sealing face is of three forms as hard chrome plating, vacuum coating andtungsten-titanium alloy and Stellite alloy etc. It owns good friction-resistance and long life for pipeline delivery of mediums withvariousin operating temperatures, high friction dust, slurry, and solid foreign matters mixture.

2、High precision ball·High tightness seat

While metal seat shows the weak point of low tightness, GJ Metal to Metal Seat Ball Valve has high tightness. It ensuresthe tightness visspring prepressing seat in case of low pressure; in case of high pressure, the tightness is secured via seatplunger effect. The key point is the original GJ ball processing technic, which ensures the high precision of the ball(roundness). Advanced seat structure and high precision ball are the main factors of high tighness. At the same time, itextremely reduces operating torque. |

|

3、Metal seat that is widely applicable

The ordinary flexible seat is easy to damage when in half-open position, while it can not be applied for cerain liquids, withnarrow range oftemperature and restricted use. GJ Metal to Metal Seat Ball Valve with high hardness metal seat is applicablefor high temperature liquid, highfriction dust, slurry, transmitter with impacting substances and solid mixtures etc. It is nearlyapplicable for all liquids.

4、 It owns all features a ball valve may have

Compared with gate valves and globe valves,GJ ball valve with metal seat bears more advantages. It has all features aball valve may have such as small flow resistance, 900 .operating valve lever for quick close, easy shift between manual andautomatic operation etc., Which facilitates the auto control.

5、The best valve to fire and static resistance safety

Metal seat is resistant to extremely high temperature of 500℃,with the function of fire and static resistance

6、The most economical material combination

The most economical point lies in that GJ Metal to Metal Seat Ball Valve selects different seals according to differentwork condition

7、Free selection of operating modes

GJ Metal to Metal Seat Ball Valve has the function that different operating mechanism can be selected according todifferent valve size and application purpose. |

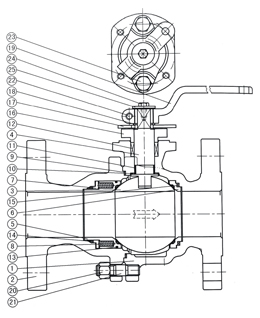

| Part Drawings(metal seat) |

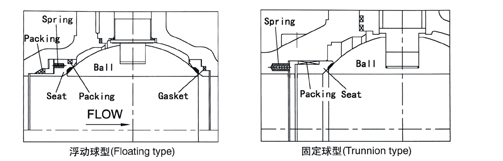

| Floating type |

ANSI CLASS 150Lb. 300Lb. 400Lb_ 600Lb. 900Lb. 1500Lb

Pn16. 25. 40. 64. 100. 160. 250 |

| Size:15-200 |

| NO. |

Part Name |

Materil |

| 1 |

Body |

A351(G) CF8 |

A351(G) CF8M |

A216(G) WCB |

| 2 |

Cap |

A351(G) CF8 |

A351(G) CF8M |

A216(G) WCB |

| 3 |

Ball |

A276(TP)304·HCr |

A276(TP)316·SFNi |

A276(TP)304·SFNi |

| 4 |

Stem |

17-4PHV·HCr |

17-4PH·N2 |

17-4PH·N2 |

5

|

Seat

|

A276(TP)316

+Stellited |

A276(TP)316

+Stellited |

A276(TP)304

+Stellited |

6

|

Lower seat

|

A276(TP)316

+Stellited |

A276(TP)316

+Stellited |

A276(TP)304

+Stellited |

| 7 |

Gland ring |

A276(TP)316 |

A276(TP)316 |

A276(TP)304 |

| 8 |

Coil spring |

INCONEL X-750 |

INCONEL X-750 |

INCONEL X-750 |

| 9 |

Gasket |

Metal&

Flexidle Graphite |

Metal&

Flexidle Graphite |

Metal&

Flaxidle Graphite |

| 10 |

Thrust bearing |

FleXilB GmDhlte |

Flexile Graphite |

FleXIlBGmDhlte |

| 11 |

Stem bearing |

Flaxile Graphite |

Flexile Graphite |

Flexile Graphite |

| 12 |

Packing |

FleXilB GmDhlte |

Flexile Graphite |

Flexile Graphite |

| 13 |

Dustproof ring |

Flaxile Graphite |

Flexile Graphite |

Flexile Graphite |

| 14 |

Packing |

FleXileGmDhlte |

Flexile Graphite |

Flexile Graphite |

| 15 |

Packing |

Flexila Graphite |

Flexile Graphite |

Flexile Graphite |

| 16 |

Gland flange |

A351(G) CF8 |

A351(G) CF8 |

WCB-ENP |

| 17 |

Stopper |

ASTM A105·ENP |

ASTM A1 05·ENP |

ASTM A105· ENP |

| 18 |

Snap ring |

ALLOY STEET |

ALLOY STEET |

ALLOY STEET |

| 19 |

Lever |

CARBON STEET |

CARBON STEET |

CARBON STEEl |

| 20 |

Nut |

A276(TP)304· N2 |

A276(TP)304·N2 |

ASTM A1 94-2H |

| 21 |

Stud |

A276(TP)304 |

A276(TP)304 |

ASTM A193-B7 |

| 22 |

Head Bolt |

A276(TP)304 |

A276(TP)304 |

ASTM A193-B7 |

| 23 |

Bolt |

A276(TP)304 |

A276(TP)304 |

ASTM A193-B7 |

| 24 |

Bolt |

A276(TP)304 |

A276(TP)304 |

ASTM A193-B7 |

| 25 |

Washer |

A276(TP)304 |

A276(TP)304 |

A105·Zn |

|

|

|

|

PC:GJ Metal to Metal Seat Ball Valve of floating ball type consists of main(recommended) and reverse flow direction.Seal level should

meet the requirement of level V stipulated by ANSI B1 6.104 when in main flow direction. Or the requirement of level IV shall be met. |

|

|