|

|

| Features |

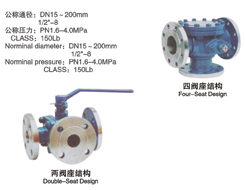

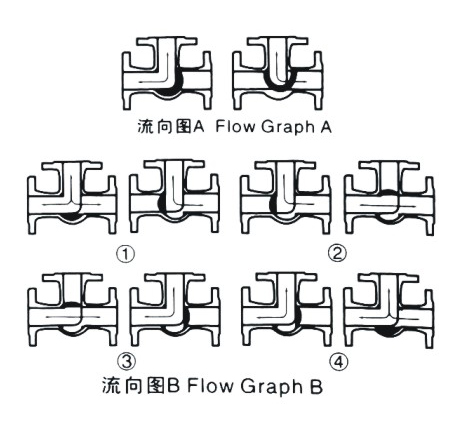

1.in the double-seat sealing design,the 3-way ball valve enjoyscompact structure,goodly configuration and favorable sealingperformance.The value could make a realization the switching offlow direction of the medium inside the pipeline,furthermore,it also could connect or shut-down the two orthogonal passages(As shown in Flow Graph A).

2.ln the 4-seat sealing design,the 3-way ball value enjoys reasonable,compact structure and goodly configuration.The value could not onlymake a realization the swithing off low direction of the medium insidethe pipeline,but also connect the 3 passages on another.Meanwhile,the value also features the capacity of shutting-down one of the 3passages while connecting the other 2 0nes for the flexible controlof the convergent flow or shunting of the medium in pipelines (As shown in Flow Graph B). |

| Main parts and Material |

Main Performance Spcification |

Accessory name

|

Material |

GB |

ASTM |

| Body、bonnet |

WCB |

A216-WCB |

Seat

|

PTFE、Counterpoint

polyphenyl |

PTFE、Counterpoint

polyphenyl |

| BajI |

1Cr18Ni9Ti |

SS 304 |

| Stem |

2Cr13 |

A276-410 |

Dual-head

double-screw bolt |

35CrMoA

|

A193-B7

| |

PN(MPa)

Norninal pressure |

(MPa)Test pressure |

| Shell |

High-pressure

liquld sealing |

Low-pressure

hermetic sealing |

| 1.6 |

2.4 |

1.76 |

0.6 |

| 2 5 |

3.75

|

2.75 |

| 40 |

6 0 |

4.4 |

| CLASS150 |

3.0 |

2.2 |

Applicabla

Specification |

Applicable

medium |

Non-corrsion medium such as water

and gas,etc,and nitric acid

corrosion medium |

Applicable

temperature |

-28 - 280℃ |

| Applicable |

Connectingflanger |

JB79-94、GB9113、 HG20592-09、ANSIB16.5 |

Operating

Mode |

Test and inspection |

JB/T9092-99. AP1598 |

| Other manufacturing standard is according to the standard of factory | |

Remarks:

Double-seat configuration design is generally utilized for 3-way ball value as shown in the 2 0pratingconditions in Folw Graph A which apply the L-Shaped construction with double-seat(Type Q44).With regard to the 2 condition of ①and ④ in flow Graph B,the T-shaped construction with double-seat could also be applied(Type Q45).ln the ② and ③ conditions in this graph, the choice of the cinstruction must be limited to T-shapedones with 4-seat(Type Q45).For other kinds of opeqating conditions, the construction with 4-seat could also be applied,however,the construction of the relevent valve seats should be referred in advance in the contractfor future delivery.For other requirements please refer to the sample of Organizing Methord for Types of Ball Valves and fill in corresponding code numbers as required. |

|

| Norminal pressure |

|

DN(mm/in)Nominal diameter |

| 15/l/2" |

20/3/4’ |

25/1" |

32/1 1/4" |

40/1’/2" |

50/2" |

65/21/2^" |

80/3" |

100/4" |

125/5" |

150/6" |

200/8" |

| PNl.6MPa |

L |

150 |

150 |

180 |

200 |

220 |

240 |

260 |

280 |

320 |

380 |

440 |

550 |

| PN2.5MPa |

L1 |

75 |

75 |

90 |

100 |

110 |

120 |

130 |

140 |

160 |

190 |

220 |

275 |

| PN4.OMpa |

H |

90 |

90 |

102 |

115 |

135 |

140 |

155 |

185 |

210 |

275 |

305 |

335 |

| CLASS 150 |

W |

140 |

140 |

155 |

250 |

250 |

350 |

350 |

420 |

700 |

1000 |

1300 |

1800 |

| Please refer to the sample book of Form of Main Type and Commecting Dimension for other flange dimensions | |

| |