一、STRUCTURES CHARACTERISTICS AND USAGE

1.The keeper type fitter holds a large filter arer and a small flow resistance coefficient on the lower end of it a freely-rinsing device is fitted,the rinse time is quicker than the general Y type ones by 8-10 times.

2.The product is used for petroleum,chemical industry,water steam,metallurgy,heat supply,and drainage etc.TO filter the foreign matter’s inside of the pipeline and different filter screens(20-180mesh)can be used upon the requirements of the users to the medium to be filtered.

3.Both inside and outside of the body are coated with non-toxic powder epoxy resin to get no rusty water and no corrosion to the body.

4.The filter screen is made of stainless steel and no rusty spot would occur with the screen,thus not reducing the filter area.

二、MAIN TECHNIQUE NUMBER

| Nominal pressure PN(MPa) |

Skell test pressure(MPa)

|

Working pressure(MPa)

|

Body material |

Sieve material |

Applicable medium |

| 1.0 |

1.5 |

1.0 |

Casting pig |

Stainless steel |

Water

Air

Oil |

| 1.6 |

2.4 |

1.6 |

Ductile Iron

Carbon steel |

| 2.5 |

3.75 |

2.5 |

Carbon steel |

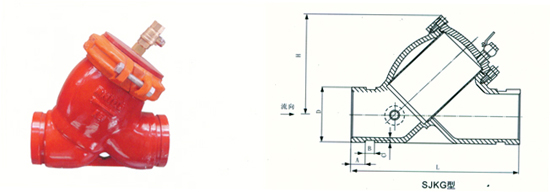

三、SCHEMATIC DIAGRAM OF INSTALLATION

| 公称通径 DN(mm) |

L |

D |

A |

B |

C |

H |

| 50 |

185 |

57 |

14.5 |

9.5 |

2.2 |

190 |

| 60 |

| 65 |

200 |

76 |

14.5 |

9.5 |

2.2 |

205 |

| 80 |

225 |

89 |

14.5 |

9.5 |

2.2 |

225 |

| 100 |

305 |

108 |

16 |

9.5 |

2.2 |

275 |

| 114 |

| 150 |

350 |

159 |

16 |

9.5 |

2.2 |

335 |

| 165 |

| 168 |

| 200 |

445 |

219 |

19 |

13 |

2.5 |

415 |

| 250 |

540 |

273 |

19 |

13 |

2.5 |

485 |

| 300 |

600 |

325 |

19 |

13 |

3.3 |

555 |

| 350 |

650 |

377 |

25 |

13 |

3.3 |

625 |

| 400 |

700 |

426 |

25 |

13 |

5.5 |

670 |

| 450 |

750 |

480 |

25 |

13 |

5.5 |

720 |

| 500 |

800 |

530 |

25 |

13 |

5.5 |

775 |

| 600 |

900 |

630 |

25 |

13 |

5.5 |

900 |

|