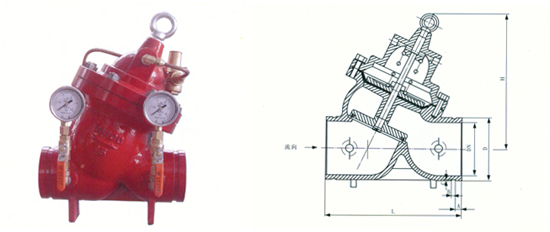

三、主要外形及连接尺寸 SCHEMATIC DIAGRAM OF INSTALLATION

| 公称通径 DN(mm) |

D |

L |

A |

B |

C |

F |

H |

| 50 |

57 |

185 |

14.5 |

9.5 |

2.2 |

250 |

250 |

| 60 |

| 65 |

76 |

200 |

14.5 |

9.5 |

2.2 |

300 |

270 |

| 80 |

89 |

225 |

14.5 |

9.5 |

2.2 |

315 |

295 |

| 100 |

108 |

305 |

16 |

9.5 |

2.2 |

340 |

310 |

| 114 |

| 150 |

159 |

350 |

16 |

9.5 |

2.2 |

400 |

375 |

| 165 |

| 168 |

| 200 |

219 |

445 |

19 |

13 |

2.5 |

470 |

425 |

| 250 |

273 |

540 |

19 |

13 |

2.5 |

520 |

475 |

| 300 |

325 |

600 |

19 |

13 |

3.3 |

620 |

570 |

| 350 |

377 |

650 |

25 |

13 |

3.3 |

700 |

650 |

| 400 |

426 |

700 |

25 |

13 |

5.5 |

780 |

730 |

| 450 |

480 |

750 |

25 |

13 |

5.5 |

850 |

800 |

| 500 |

530 |

800 |

25 |

13 |

5.5 |

930 |

870 |

| 600 |

630 |

900 |

25 |

13 |

5.5 |

1100 |

950 |

This valve utilizes the self enery of a medium to adjust the pipeline pressure and controls the outlet pressure of the main valve via the adjustment of the pressure reducing pilot valve .The outlet pressure does not change along with the variation of the variation of the inlet one and of the water quantity at the outlet .Reliable sealing performance ,easy intallation ,maintenance ,debugging and check,long duration.

二、FEATURE

1.Reliable pressure reducing effect.The outlet pressure will not be influenced by either the inlet pressure or the flow variation,both dynamic and static pressures can be reduced.

2.Easy debugging and operation.Just adjusting the adjustable screw of the pilot valve can get an accurate and stable outlet pressure.

3.Good effect of energy saving.The valve body is so designed as full-path streamline straight-flow type,resuling in a small pressure loss,a big flow,a small volume and a light weight.

三、 SCHEMATIC DIAGRAM OF INSTALLATION

| 公称通径 DN(mm) |

D |

L |

A |

B |

C |

F |

H |

| 50 |

57 |

185 |

14.5 |

9.5 |

2.2 |

250 |

250 |

| 60 |

| 65 |

76 |

200 |

14.5 |

9.5 |

2.2 |

300 |

270 |

| 80 |

89 |

225 |

14.5 |

9.5 |

2.2 |

315 |

295 |

| 100 |

108 |

305 |

16 |

9.5 |

2.2 |

340 |

310 |

| 114 |

| 150 |

159 |

350 |

16 |

9.5 |

2.2 |

400 |

375 |

| 165 |

| 168 |

| 200 |

219 |

445 |

19 |

13 |

2.5 |

470 |

425 |

| 250 |

273 |

540 |

19 |

13 |

2.5 |

520 |

475 |

| 300 |

325 |

600 |

19 |

13 |

3.3 |

620 |

570 |

| 350 |

377 |

650 |

25 |

13 |

3.3 |

700 |

650 |

| 400 |

426 |

700 |

25 |

13 |

5.5 |

780 |

730 |

| 450 |

480 |

750 |

25 |

13 |

5.5 |

850 |

800 |

| 500 |

530 |

800 |

25 |

13 |

5.5 |

930 |

870 |

| 600 |

630 |

900 |

25 |

13 |

5.5 |

1100 |

950 |

|