The structured of our butterfly valves are centered seal, single eccentric seal, double eccentric seal, triple eccentric seal and variable eccentric seal. The sealing principles of these structures are stated as following.

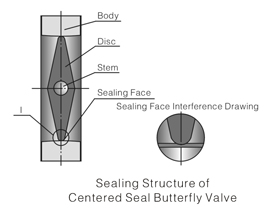

1. Sealing Principle of Centered Seal Butterfly Valve

With the disc seal center of butterfly valve and rotation center of stem overlapped, sealing load will be produced between the sealing faces of seat and disc under certain magnitude of interference, thus to ensure effective seal of valve. Lined with rubber on body, this structure is applicable for medium and small-bore butterfly valves. Due to the deformation under extrusion, during the process of opening and closing, disc is always under extrusion. So, the upper and lower valve shafts are seriously extruded, which can be bad to the service life of valve. And, the open-close moment of valve is relatively high. The defect is that disc and seat are always under extrusion, scratch, high resistance andserious abrasion. To overcome extrusion and scratch and to ensure good seal, seat basically uses rubber or PTFE, or other elastic materials. However, temperature can be a problem. This is why butterfly valves are, conventionally, not resistant to high temperature.

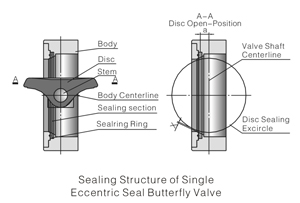

2. Sealing Principle of Single Eccentric Seal Butterfly Valve

The rotation center of disc (namely center of valve shaft) and the sealing section of disc form up an a eccentric, making disc sealing face gradually disengaged from seat sealing face during the process of open and close. Once the disc turns to 15°~25°,the disc sealing face will be completely disengaged from the seat sealing face. Once fully opened, a gap X will be formed up between the two sealing faces, making the relative mechanical wear and extrusion between the two sealing faces greatly lowered during the process of open and close, thus to ensure the seal of butterfly valve. However, as the scratch between disc and seat doesnt disappear during the whole process of open and close, they are almost similar to concentric butterfly valves in the area of application, this is why they have not been popularly used.

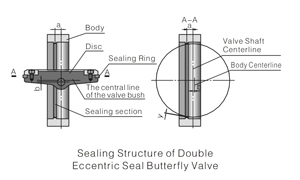

3. Sealing Principle of Double Eccentric Seal Butterfly Valve

The rotation center of disc (namely the center of valve shaft) and the centerline of body form up a b eccentric on the base of single eccentric butterfly valve, making the sealing face of disc disengaged from seat sealing face more quickly than single eccentric seal butterfly valves during the process of open and close. Once disc turns to 8°~12°, the disc sealing face will be completely disengaged from the seat sealing face. Once fully opened, a gap Y will be formed up between the two sealing faces. This type of butterfly valves are designed to have greatly lowered the mechanical wear and extrusion deformation between the two sealing faces, making the sealing performance of butterfly valve much better.

The characteristic of this structure is to make stem axis not only deviated from the center of disc, but also the center of the body. The effect of double eccentric is that, when valve has been opened, disc can be quickly disengaged from seat, thus to greatly eliminate the unnecessary excessive extrusion and scratch between the disc and seat, reduce opening resistance, lower the abrasion and improve the service life of seat. As scratch has been greatly lowered, metal seat can be used for double eccentric butterfly valve, so that butterfly valves are able to be used in high temperature fields. However, as its seal is positioned sealing construction, i.e. the sealing faces disc and seat is lineal contact, disc extruding seat to produce elastic deformation, thus to effect the sealing performance. This has high requirement on close position, especially for those with metal seat, and is given poor pressure endurance. This is why butterfly valves are, conventionally, not resistant to high temperature and leakage.

[1] [2] [3] [4] 下一页 |