| 1、产品特点Features |

本系列气动球阀是作为控制含尘、含固体粉末,特别适用于高炉煤粉喷吹、空气管路及喷**管路系统。

01、阀座带有磨损自动补偿装置,有效确保阀门的密封性能。

02、特殊材料制成的密封圈,具耐高温、耐磨损、适用寿命长的特点。

03、阀门结构紧凑、启闭灵活、安装维修方便。

The Pneumatic operated ball valve series are designed for controlling the powders containing dusts or solid bodies,especially for those fields or systems as coal-powder injection in high-fumace,airflow lines, lance lines,etc.

01 .Wear-auto-compensation equipment is applied with the valve seatto effectively ensure the sealing performance of the valve.

02.The seal ring made from exotic materials features such spe-e ialtiesas high-temperature resistance, abrasion-resistance, long service-life,etc.

03.The valve bears those characteristice like compact structure, flexible on-off,and convenient method for installation and mainte-nance. |

| 2,主要零件及材质Main Parts and Matenrials |

3、技术规范Technical Specification |

| 零件名称Accessory name |

材质Materials |

| 阀体、阀盖Body、bonnet |

WCB |

球体、阀座Ball、seat

|

1 Cr18Ni9Ti+硬铬

ICr18Ni9Ti+Hard chrome |

| 阀杆Stem |

2Cr13 |

| 密封圈Sealing ring |

特种耐磨耐高温四氟

Special wearing-resising

and high-terperature

resistance tetraf luoine |

| 螺栓Bolt |

中碳钢Medium Carbon stell |

|

|

| 设计依据Design Reference |

GB系列GB series |

| 结构长度按Structural length follows |

GB1221-89 |

| 法兰尺寸按Flange Dimension follows |

GB9113、JB79-59 |

| 检验试验按Ftest and inspection follows |

JB/T9092-99 |

| 驱动方式Driving manner |

手动、气动Manua/Pneumatic |

| 适用温度Applicable Temperature |

-28-300℃ |

| 适用介质Applicable Mediums |

含尘气体、煤粉等

Dusty gases、Powder coai、etc |

| 公称压力Nominal pressure |

1.6Mpa |

| 壳体试验压力Shell Test Pressure |

2.4Mpa |

| 高压液密封High-Pressure Liquid Sealing |

1.76Mpa |

| 低压气密封Low-Pressure Hermetic Sealing |

0.6Mpa |

|

|

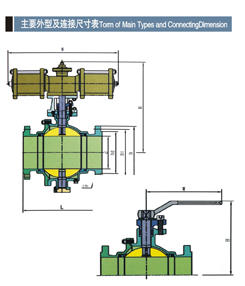

| |

| 公称压力 |

公称通径 |

尺寸dimension(mm) |

PN( MPa)

Nominal |

DN( MM)

Nominal |

|

W |

H |

pressure

|

Diameter

|

L

|

手动

Manual |

气动

Pneumatic |

手动

Manual |

气动

Pneumatic |

| |

25 |

180 |

140 |

235 |

90 |

298 |

| |

32 |

200 |

155 |

235 |

107 |

304 |

| |

40 |

220 |

250 |

330 |

127 |

370 |

| |

50 |

220 |

250 |

330 |

140 |

376 |

| |

65 |

241 |

350 |

400 |

164 |

425 |

| |

80 |

283 |

350 |

510 |

177 |

484 |

| 1.6 |

100

|

305

|

420

|

510

|

206

|

531 |

| |

125 |

356 |

700 |

580 |

292 |

570 |

| |

150 |

394 |

1000 |

720 |

320 |

570 |

| |

200 |

457 |

|

720 |

|

610 |

| |

250 |

533 |

|

900 |

|

670 |

| |

300 |

610 |

|

1050 |

|

740 |

| |

350 |

686 |

|

1290 |

|

790 |

| |

400 |

762 |

|

1600 |

|

905 |

其余连接尺寸请参阅样本《主要外型与连接尺寸表达式》

Pleasr refer to the sample book of Form of Main Types and

Connecting Dimension for other connection dimensions |

|

|

| |